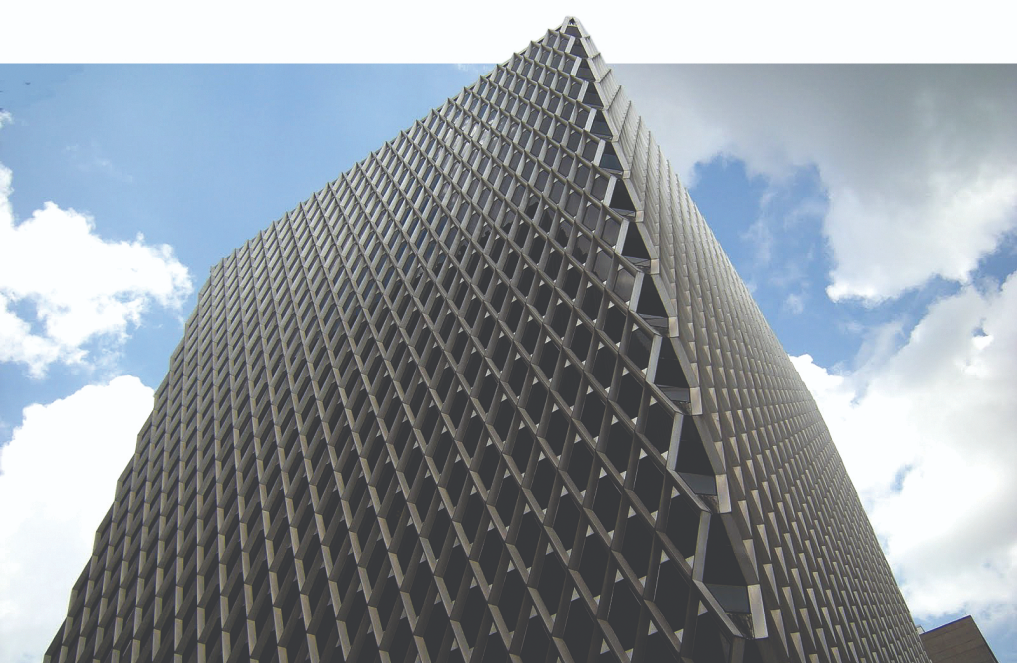

United Steelworkers Headquarters

Comprehensive Energy Efficiency

Completed in 1964 and originally named the IBM Building, the 172-foot tall United Steelworkers Building pioneered the use of both a load-bearing steel diagrid exoskeleton design and framed tube construction.

The building is supported by a steel exoskeleton resting on eight piers, two on each side of the building. Another intelligent part of the building’s structural engineering is the specification of different grades of steel depending on the strength requirements of each structural member.

The United Steelworkers (USW) turned to TEN to realize their energy efficiency goals for their headquarters building. Working with TEN, the USW achieved a 40% reduction in building energy and water consumption and earned LEED certification.

TEN’s project delivered:

- Comprehensive building energy/sustainability analysis

- Installed high-efficiency natural gas boilers

- Installed modernized elevators

- Upgraded new emergency generator

- Implemented extensive water efficiency equipment

- Modernized HVAC control systems and variable frequency mechanical systems

- Modernized building envelope energy efficiency features

- Installed renewable solar domestic water heater system

By the numbers

$203K

Annual Guaranteed Energy Savings

$80K

Rebates Secured

1.1M

kWh Electricity Saved Annually

2,500

MCF of Gas Saved Annually

859K

Gallons of Water Saved Annually

1,326

Tons of CO₂ Reduced Annually (Projected)

LEED Certification

Acheived